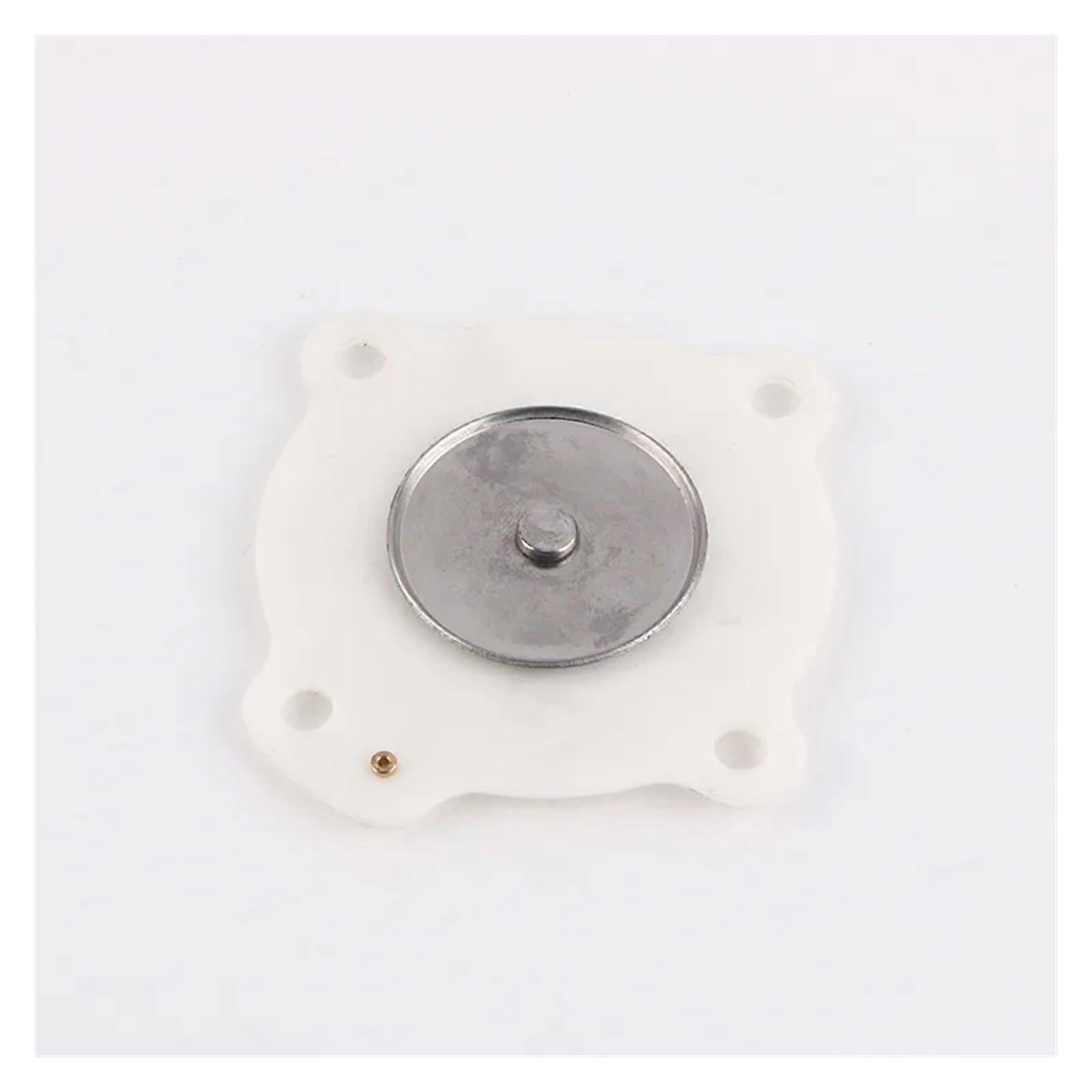

Electromagnetic Pulse Valve Diaphragm SCG353A044 A043 Dust Removal Valve Diaphragm

ÜCRETSİZ Kargo

Electromagnetic Pulse Valve Diaphragm SCG353A044 A043 Dust Removal Valve Diaphragm

- Marka: Unbranded

Electromagnetic Pulse Valve Diaphragm SCG353A044 A043 Dust Removal Valve Diaphragm

- Marka: Unbranded

| Önerilen Perakende Fiyatı: | |

| Fiyat: | |

| Kazancınız: | ₺600,00 (33%) |

Stokta var

14 Günlük İade Politikası

Biz aşağıdaki ödeme yöntemlerini kabul ediyoruz

Tanım

Electromagnetic Pulse Valve Diaphragm SCG353A044 A043 Dust Removal Valve Diaphragm

- Marka: Unbranded

- Kategoriye Göre: Su Tesisatı Vanaları

- Fruugo Kimliği: 375907553-813574527

Ürün Güvenlik Bilgileri

Lütfen aşağıda özetlenen bu ürüne özel ürün güvenlik bilgilerine bakın.

Aşağıdaki bilgiler bu ürünü satan bağımsız üçüncü taraf perakendeci tarafından sağlanmaktadır.

Teslimat ve İade

24 saat içinde kargoya verilir

-

STANDARD: ÜCRETSİZ - Arasında teslimat Per 25 Aralık 2025–Pzt 12 Ocak 2026 - ÜCRETSİZ

Kargo çıkış noktası Çin.

Sipariş ettiğiniz ürünlerin size bütün ve belirttiğiniz özelliklere göre teslim edilmesi için elimizden gelenin en iyisini yapıyoruz. Fakat, bütün gelmeyen veya siparişiniz ettiğinizden farklı çıkan bir ürünün elinize ulaşması ya da siparişinizden başka bir sebepten ötürü memnun kalmamanız durumunda, siparişi veya siparişe dahil ürünlerden herhangi birini iade edebilir ve ürünler için tam para iadesi alabilirsiniz. Tam iade politikasını görüntüle

Ürün Uyumluluk Ayrıntıları

Lütfen aşağıda özetlenen bu ürüne özel uyumluluk bilgilerine bakın.

Aşağıdaki bilgiler bu ürünü satan bağımsız üçüncü taraf perakendeci tarafından sağlanmaktadır.

Üretici:

Aşağıdaki bilgiler, Fruugo tarafında satılan bahsi geçen ürünün üreticisinin irtibat bilgilerini ortaya koymaktadır.

- DelightDew

- Shenzhen Tumi Technology Co., Ltd.

- 202-03, Jinhe Building, 8 Xinhe Street, Maan Tang, Bantian

- Longgang, Shenzhen, Guangdong

- China

- Shenzhen

- CN

- 518129

- pettynfnef@outlook.com

- 13332965772

AB sınırları içerisindeki Sorumlu Kişi:

Aşağıdaki bilgiler AB sınırları içerisindeki Sorumlu Kişi’nin irtibat bilgilerini ortaya koymaktadır. Sorumlu kişi AB içerisinde konumlu olan atanmış iktisadi işlemcidir, Avrupa Birliği içerisinde satılan bahsi geçen ürün ile ilgili uygunluk yükümlülüklerinden sorumludur.

- Synertrade FR SAS

- Synertrade FR SAS

- 9 rue du Bat d'Argent

- Lyon

- France

- Lyon

- FR

- 69001

- info@syner-sarl.cn

- (+33)774555006

- https://seller.kuajingmaihuo.com/settle/qualification-service